OEM / CUSTOMIZED

See More Categories

Product categories

- Welding

- Trailer Accessories

- Stamping & Laser Cutting Parts

- Stamping

- Precision Tools Machining

- Motorcycle Accessories

- Machining Parts

- Laser Cutting

- Investment Casting

- Injection Molding

- Gravity Casting

- Finished Products

- Drilling & Tapping

- Die Casting

- Components & Assembly Parts

- CNC Machining

- Casting Parts

- Bike Carrier Racks

- Automobile Accessories

- Aluminum Ramps

- Aluminum Boxes

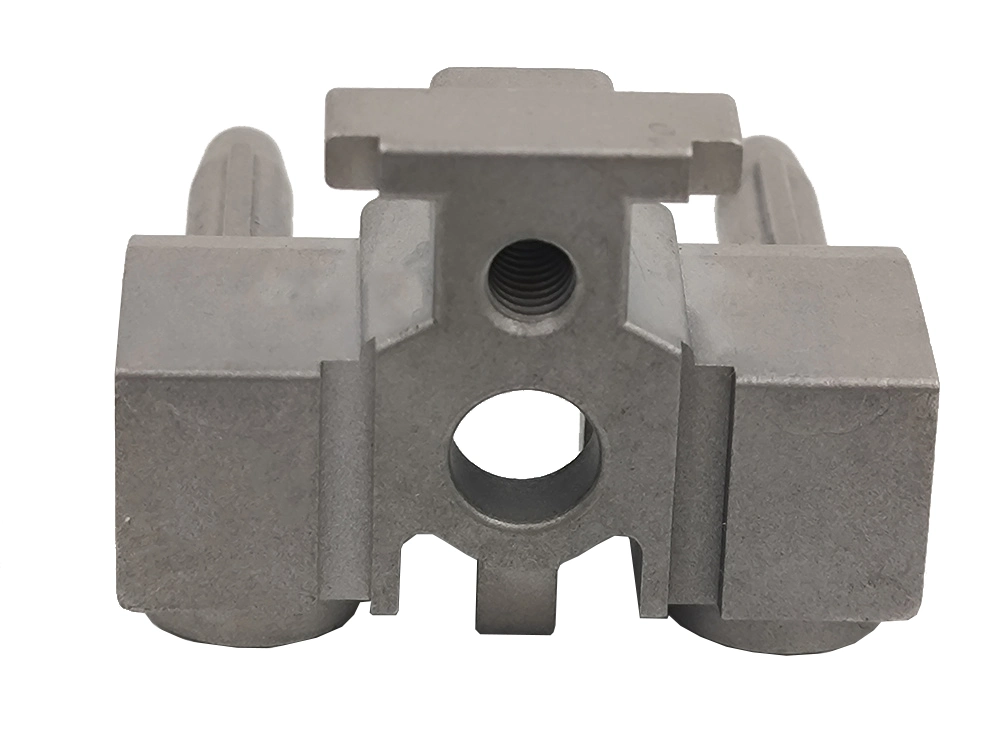

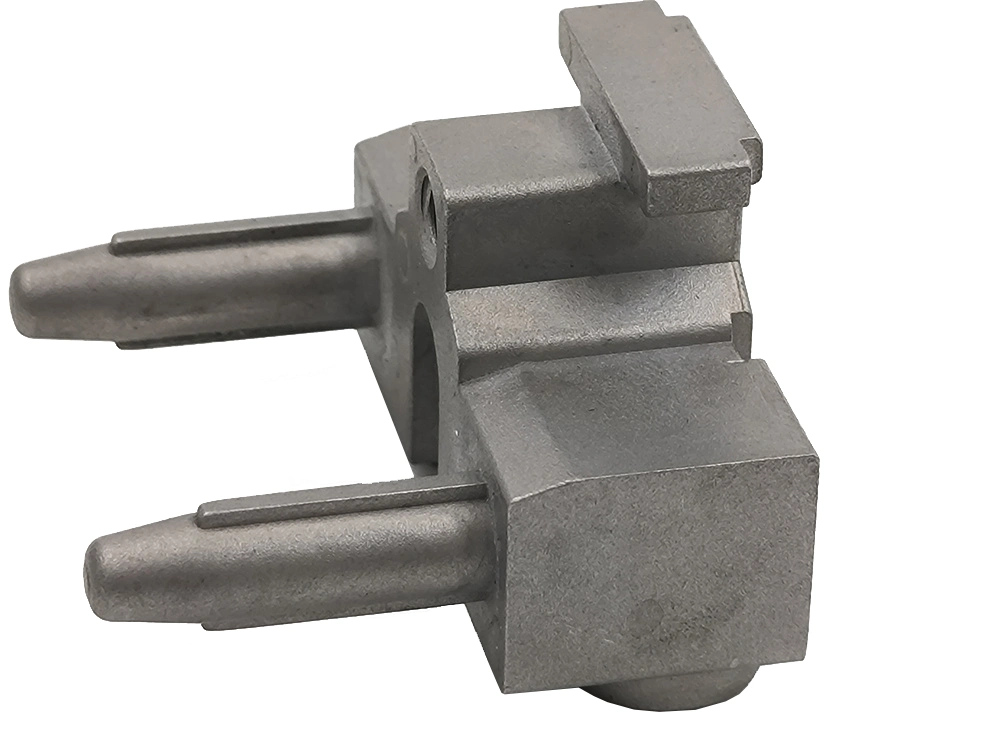

Injection Fine Steel Parts

At Ezlee, we are committed to delivering uncompromising quality and durability in every steel component we manufacture. Our Injection of Fine Steel Parts process follows rigorous quality control measures to ensure that each part meets the highest standards of excellence.

We meticulously select the finest grades of steel and utilize advanced molding techniques to ensure uniformity, strength, and dimensional accuracy in our steel components. With strict adherence to industry standards and meticulous inspection protocols, we guarantee that our fine steel parts meet or exceed your expectations.

Product Description

Injection fine steel parts combine plastic injection molding with metal powder fusion. A fine metal powder is mixed with a binder and injected into a mold—when the part is finished the binder is removed, leaving a metal part or structure that is then sintered into its final form. injection fine steel parts is a cost-effective process, especially when producing complex or unusually shaped parts at high volumes (which helps offset the expense of making the mold).

EZLEE places an emphasis on understanding the specifications and customer quality requirements, and established a whole process quality control system, which is certified to ISO9001:2008, to cover the critical quality control on site, including the raw material, initial samples, process dimensions, mechanical character, surface treatment, packing and delivery.

Specifications:

A wide variety of metals can be processed with injection fine steel parts, including stainless steel, steel alloys, iron-nickel alloys, cobalt alloys, tungsten alloys, and ceramics. Alloys can be customized for highly specific functions—for example, nickel and cobalt concentrations in carbon steel formulas can be modified for high-temperature automotive applications.

Properties:

Because making a part with injection fine steel parts require only a single mold, the process is highly repeatable and produces parts consistent in size, shape, and strength. The process can also be easily automated for high-volume production and even higher quality. Most finishes on injection fine steel parts parts are inferior compared to standard CNC machining and require secondary processes for smoother finishes and tight tolerances.

Send Inquiry

If you would like to have a question then get in touch today, we are ready to assist 24/7. We welcome your cooperation and we will develop with you.

- Factory-direct Connectivity Solutions.

- High quality, Competitive Price.

- Custom-tailored solutions.

- Problem-solving approach.