OEM / CUSTOMIZED

See More Categories

Product categories

- Welding

- Trailer Accessories

- Stamping & Laser Cutting Parts

- Stamping

- Precision Tools Machining

- Motorcycle Accessories

- Machining Parts

- Laser Cutting

- Investment Casting

- Injection Molding

- Gravity Casting

- Finished Products

- Drilling & Tapping

- Die Casting

- Components & Assembly Parts

- CNC Machining

- Casting Parts

- Bike Carrier Racks

- Automobile Accessories

- Aluminum Ramps

- Aluminum Boxes

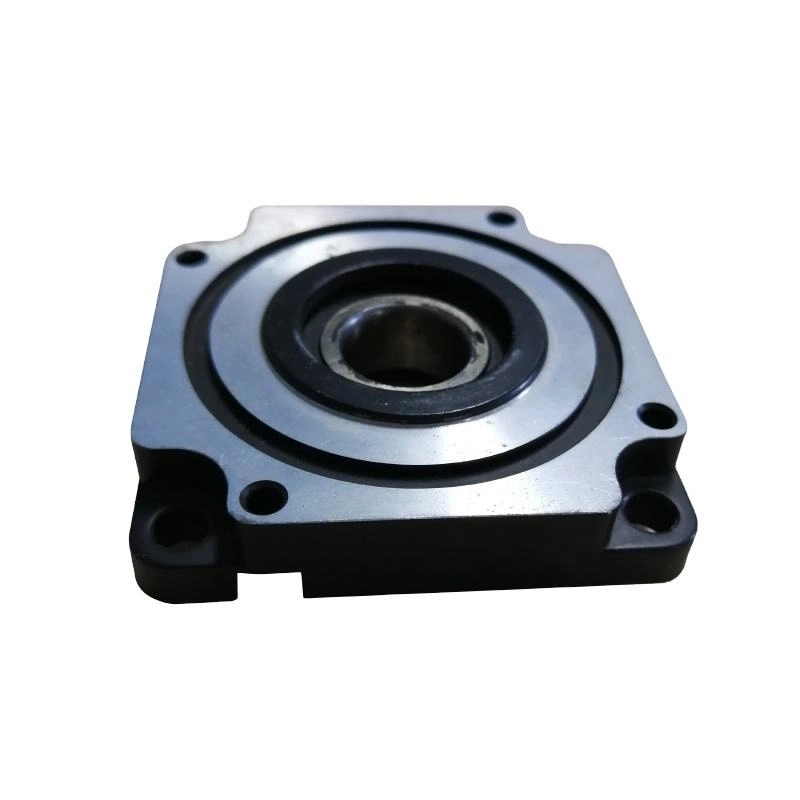

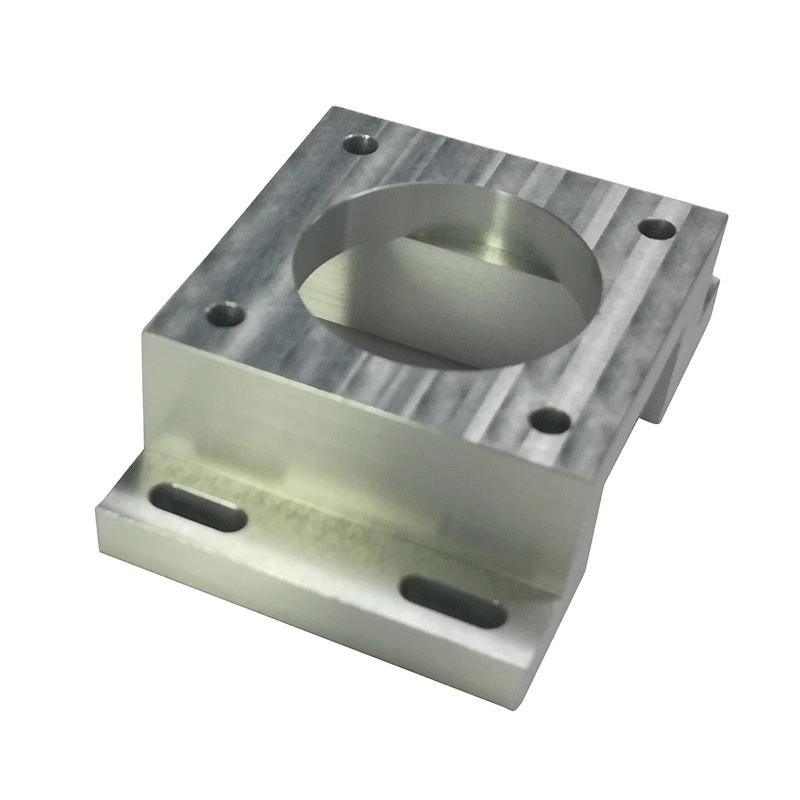

Zinc Die Casting

Step into a world of limitless possibilities with our cutting-edge zinc die casting solution. Zinc, a versatile and lightweight metal, takes center stage in our casting process. Its exceptional properties allow for intricate designs, complex geometries, and high dimensional accuracy. With our zinc die casting solution, you can unlock the true potential of your manufacturing projects, whether you’re creating automotive components, electronic enclosures, or decorative hardware.

Product Description

Zinc die casting is cast with the fast-cycling hot chamber die casting process, which utilizes a component called a gooseneck that is submerged in a furnace filled with molten metal. Metal automatically enters the shot chamber through a hole in the gooseneck. A vertical plunger then seals the hole and drives the metal into the back of the die with high pressure. The part rapidly solidifies (within seconds), and the part is ejected from the tool. EZLEE places an emphasis on understanding the specifications and customer quality requirements, and established a whole process quality control system, which is certified to ISO9001:2008, to cover the critical quality control on site, including the raw material, initial samples, process dimensions, mechanical character, surface treatment, packing and delivery.

Properties:

- Longer tool life

- Lower tooling cost (particularly if it can use the miniature zinc die casting process)

- The ability to cast near net-shaped complex geometries with thinner walls and less draft angle than castings produced with other metals reduces the need for machine features

- Excellent balance of mechanical and physical properties, including higher yield strength and elongation when compared to aluminum or magnesium

- Good vibration dampening capacity compared to aluminum

- Wide range of finishing options

- Faster production time

Specifications:

| Process | Zinc Die Casting |

| Weight | Higher |

| Melting point | Low |

| Thermal conductivity | High |

| Corrosion resistance | Higher |

| Tooling life | High tool longevity |

| Surface finishing | Low |

| Applications | Automotive, marine, and electronic industry

Power steering system Engine component Fuel System |

| Cycle time | Ten times higher |

| Costs | High |

Send Inquiry

If you would like to have a question then get in touch today, we are ready to assist 24/7. We welcome your cooperation and we will develop with you.

- Factory-direct Connectivity Solutions.

- High quality, Competitive Price.

- Custom-tailored solutions.

- Problem-solving approach.